Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

Product Introduction

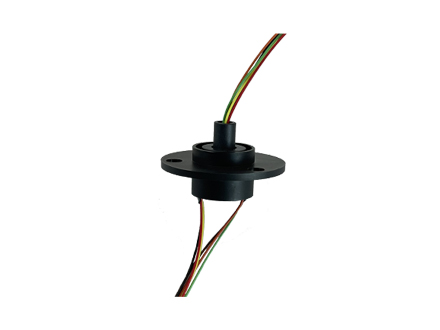

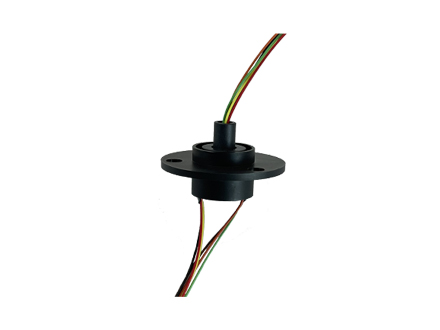

Reehonde specializes in providing 6 Wire Slip Ring customization services. This conductive Slip Ring is exquisitely designed and powerful, suitable for various industrial applications that require rotation to transmit power and signals. Our 6 Wire Slip Ring has become the first choice of many customers for its excellent performance and reliability.

This conductive Slip Ring is made of high-quality conductive materials and engineering plastics, and is processed through precision processes to ensure that it can operate stably in various harsh environments. The slip ring uses gold-to-gold contact material to ensure low electrical noise and longer service life. At the same time, it also has a compact structural design for easy installation and maintenance.

Product Features

Gold-to-gold contact material: The use of gold-to-gold contact material ensures the long life and low electrical noise of the slip ring, which is particularly suitable for small and medium-sized equipment to transmit weak signals.

Low torque, low electrical noise and smooth rotation: The slip ring design has low torque characteristics, ensuring that there will be no excessive friction and noise during rotation, while ensuring smooth rotation.

Small and compact structure: The compact structural design enables it to easily adapt to application scenarios with limited space, and is also convenient for installation and maintenance.

Compatible with data bus protocols: supports multiple data bus protocols, such as Ethernet, USB, RS, Canbus, etc., to meet different data transmission requirements.

360-degree unlimited rotation transmission: can continuously transmit signals and/or data under 360-degree unlimited rotation to ensure stable operation of the equipment.

Customization options: provide a variety of customization options, including number of circuits, current and voltage, working speed, shell material and color, protection level, lead withdrawal direction, connector type, and signal and power transmission methods, etc., to meet the specific needs of customers.

Application areas

CCTV monitoring system: used for power and signal transmission of rotating parts of the camera to ensure the stability and clarity of the monitoring screen.

Rotating tables and exhibition/display equipment: In rotating tables and exhibition equipment, slip rings are used to transmit power and signals to ensure the normal operation and display effect of the equipment.

Robots: In robot systems, conductive slip rings are used to transmit power and control signals, enabling robots to flexibly perform various actions.

Medical equipment: Rotating parts are often required in medical equipment. Conductive slip rings can ensure the power and signal transmission of these parts to ensure the accuracy and reliability of the equipment.

Wind turbine: In wind turbine, conductive slip ring is used to transmit power and monitor signals to ensure the stable operation of wind turbine.

Industrial process equipment: In various industrial process equipment, conductive slip ring is used to transmit power and signals to ensure the normal operation and production efficiency of equipment.

Installation method

Check accessories: After receiving the slip ring, please open all packages and check whether all accessories are complete and intact. If there is any damage or missing, please contact the manufacturer in time for replacement.

Turn off the power equipment: Before installation, all power equipment to be connected needs to be turned off to prevent dangerous accidents caused by electric shock during wiring.

Remove or loosen the screws: Remove or loosen the screws at the rotor end and stator end until the slip ring is pre-installed in the set fixed position.

Install the slip ring: Place the slip ring in the predetermined position, ensure that the color sequence of the output wires at the rotor end and the stator end corresponds one by one, and then tighten the screws step by step. Remember not to overload the screws to avoid screw stripping.

Wiring: Wiring according to the correct wiring diagram to ensure no wrong connection or missing wiring. The color sequence of the wires at the rotor and stator ends of the slip ring must correspond to each other to prevent short circuit or damage to the slip ring due to wrong wiring.

Inspection: After installation, please carefully check the installation of the slip ring to ensure that all screws are tightened and the slip ring can rotate smoothly.

FAQ

Q1: What is a conductive slip ring?

A1: A conductive slip ring is a device used to transmit power or signals between two objects that rotate relative to each other. It is usually installed at the rotation center of the equipment and consists of a rotating part (rotor) and a stationary part (stator). It transmits power and signals through key components such as elastic materials and conductive rings.

Q2: What types of signals can 6 Wire Slip Ring transmit?

A2: 6 Wire Slip Ring can transmit many types of signals, including low-frequency signals (such as audio signals, analog video signals, etc.), Ethernet, USB, RS, Canbus, FireWire, etc., as well as servo motor signals, encoder signals, strain gauge signals, thermocouple signals, etc.

Q3: What are the rated voltage and rated current of 6 Wire Slip Ring?

A3: The rated voltage of 6 Wire Slip Ring is usually 240V(depending on the model), and the rated current is 2A/circuit or signal (depending on the model and customization requirements).

Q4: How to choose a suitable conductive slip ring?

A4: When choosing a suitable conductive slip ring, you need to consider multiple factors, including the number of circuits, current and voltage, operating speed, shell material and color, protection level, lead withdrawal direction, connector type, and signal and power transmission methods. Please contact Reehonde's customer service team according to your specific needs, and we will provide you with professional advice and customized services.

Q5: What is the life of a conductive slip ring?

A5: The life of a conductive slip ring depends on multiple factors, including rotation speed, working environment and temperature. Generally speaking, conductive slip rings with gold-to-gold contact materials have a longer service life. At the same time, proper installation and maintenance can also extend the service life of the conductive slip ring.

Q6: How to maintain the conductive slip ring?

A6: The maintenance of the conductive slip ring mainly includes regular inspection of the contact and wear of the slip ring, as well as cleaning the dust and dirt on the surface of the slip ring. If the slip ring is found to be worn or in poor contact, please contact Reehonde's customer service team for replacement or repair.

Q7: Are the conductive slip rings customizable?

A7: Yes, Reehonde provides customized services for conductive slip rings. We can customize the number of circuits, current and voltage, operating speed, housing material and color, protection level, lead withdrawal direction, connector type, and signal and power transmission methods according to your specific needs. Please contact our customer service team for more customization details.

Q8: In what fields are conductive slip rings used?

A8: Conductive slip rings are widely used in many fields, including CCTV monitoring systems, rotating tables and exhibition/display equipment, robots, medical equipment, wind turbines, and industrial process equipment. These fields require the transmission of power and signals between rotating parts, and conductive slip rings are the ideal choice to solve this problem.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions