Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

Product Details

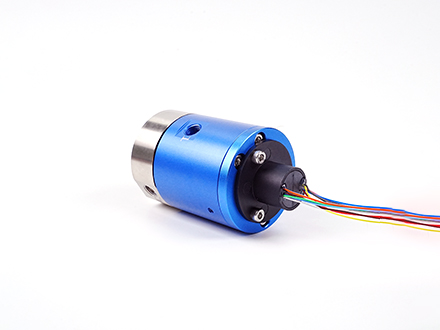

Rotating electrical connection, often referred to as a rotary union or slip ring, is a device designed to enable the transfer of various media—including compressed air, steam, vacuum, nitrogen, hydrogen, and other inert gases—and electrical signals through a continuous 360-degree rotation. This technology integrates both fluid and electrical pathways within a compact assembly, enabling seamless connectivity in dynamic applications where traditional fixed connections are impractical.

One particular variant, incorporating an air slip ring, offers a robust solution for conducting compressed air and other gases along with electrical signals. These slip rings utilize special materials for sealing surfaces and gaskets, ensuring resistance to wear, longevity, corrosion protection, and zero leakage.

Key Features

Media Compatibility: Capable of conducting compressed air, nitrogen, and other inert gases.

Compact Design: Small size and lightweight, reducing space requirements and mechanical load.

Signal Integration: Ability to integrate power, switching signals, Ethernet, USB, industrial buses, sensor signals, and more.

Customization: Customizable rotary joint parameters and integrated conductive slip ringstailored to client specifications.

Flexible Configurations: Options for inner and outer diameters, number of circuits, current and voltage ratings, wire lengths, connection terminals, housing materials and colors, ingress protection ratings, and combined or separate transmission of signals and power.

Functionalities

Fluid and Signal Transmission: Simultaneously transmits gases and electrical signals without interruption during rotation.

Continuous Rotation: Maintains connection integrity over continuous, unrestricted rotational movements.

Durability: Special materials and design ensure long-term reliability and minimal maintenance.

Multi-channel Capability: Supports multiple circuits for a variety of signals and media.

Application Domains

Industrial Automation Equipment: Enables smooth operation of robotic arms, conveyors, and other automated machinery.

Packaging Equipment: Facilitates the handling and sealing of packaging materials in dynamic assembly lines.

Semiconductor Equipment (e.g., SMT Machines): Ensures reliable connections for vacuum systems, cooling gases, and control signals in precise manufacturing processes.

Testing Equipment: Supports rotating testing platforms with continuous data acquisition and control signal transmission.

Robotics: Provides continuous power and signal transfer for mobile, articulated robots and manipulators.

Installation Instructions

Matching Mounting Points: Ensure the slip ring's mounting position aligns with the equipment. Pre-connect the rotor-side tubing securely to prevent leaks.

Concentricity Adjustment: Before final fixation, adjust the rotor's concentricity to guarantee smooth rotation of the slip ring.

Anti-rotation Measures: Secure the stator side using an anti-rotation pin or a custom-made rotational joint as per requirements.

Maintenance and Servicing

Regular Inspections: Conduct periodic checks for signs of wear, leakage, or corrosion.

Cleaning: Use approved cleaners to remove dirt and debris from sealing surfaces and connections.

Lubrication: Apply suitable lubricants to moving parts as recommended by the manufacturer.

Tightening: Periodically check and tighten all mounting bolts to prevent loosening.

Replacement of Seals: If leaks are detected, replace worn seals with genuine spare parts.

Installation Precautions

Handling and Storage: Avoid impact and dropping during transportation and storage to prevent damage to the interfaces and internal components.

Bolt Tightening: Secure bolts with locking mechanisms to prevent loosening over time.

Thread Orientation: Ensure the threads of the rotating joint's inner and outer tubes match the direction of rotation and are consistently oriented.

Media Filtering: Connect the rotating joint directly to flexible tubing, and use filters to remove impurities from the media entering the slip ring.

Proper Support and Anti-rotation: Ensure the rotating joint is adequately supported and the anti-rotation mechanism allows for some freedom of movement to avoid binding.

Additional Considerations

Environmental Factors: Choose materials and designs suitable for the specific operating environment, considering temperature, humidity, chemical exposure, and other factors.

Electromagnetic Compatibility (EMC): Ensure the slip ring's design complies with EMC standards to prevent interference with other electronic systems.

Training: Provide adequate training to personnel responsible for installation, maintenance, and troubleshooting to ensure proper handling and extended equipment lifespan.

In summary, rotating electrical connections represent a versatile and crucial technology in various industrial and automated applications. Their ability to transmit fluids and signals seamlessly through continuous rotation makes them indispensable in complex machinery and systems. By adhering to installation guidelines, performing regular maintenance, and paying attention to detail during operation, users can maximize the reliability and longevity of these sophisticated devices.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions