Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

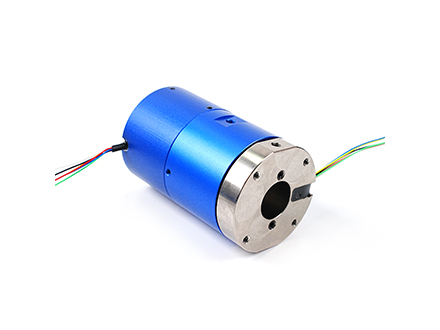

Definition

Electrical Rotary Joint is a device that can realize the transmission of electrical signals and fluid media (such as compressed air, steam, vacuum, nitrogen, hydrogen and other inert gases) between rotating parts and fixed parts.

It combines the functions of conductive slip rings and gas slip rings, and can transmit both electrical signals and fluid media. It is widely used in various occasions that require rotational transmission.

Features

Diversity of media: The conductive media include compressed air, nitrogen and other inert gases, as well as various control signals.

Compact structure: small size, light weight, small torque, easy to integrate into various devices.

Signal integration: It can integrate power, switch signals, Ethernet, USB, industrial bus, sensor and other signals to meet various transmission needs.

Customized service: According to customer requirements, the parameters of the rotary joint and the integrated conductive slip ring can be customized, and options such as inner diameter, outer diameter, number of paths, current & voltage, wire length, connection terminals, shell material and color, protection level, etc. can be provided.

High performance: The sealing surface and sealing ring are made of special materials, which are wear-resistant, long-life, corrosion-resistant, and leak-proof, ensuring the stability and reliability of transmission.

Function

Electrical signal transmission: Through the conductive slip ring part, various control signals, data signals, etc. are transmitted.

Fluid medium transmission: Through the air slip ring part, compressed air, steam, vacuum, nitrogen, hydrogen and other inert gases are transmitted.

Rotational transmission: Supports 360-degree rotation of the conductive medium, suitable for various occasions requiring rotational transmission.

Application field

Industrial automation equipment: used for various rotating parts on the automated production line to realize the transmission of electrical signals and fluid media.

Packaging equipment: In packaging machinery, it is used to transmit packaging materials, control signals, etc.

SMT equipment: In semiconductor manufacturing equipment, it is used to transmit chips, control signals, etc.

Test equipment: In the test system, it is used to transmit test signals, test media, etc.

Robot: In the robot system, it is used to transmit the robot's control signal, power signal, etc., to achieve flexible movement of the robot.

Installation and maintenance

Installation instructions

Match the installation position: Make sure that the installation position of the slip ring matches the equipment. It is necessary to connect the air pipe to the rotor end first to ensure that there is no air leakage/liquid leakage.

Adjust the concentricity: Debug the concentricity of the rotor before installation and fixation to ensure smooth rotation of the slip ring.

Stop rotation fixation: The stator end of the slip ring is screwed into the stop rod through the stop hole to stop rotation. The rotary joint can also be customized according to customer needs.

Maintenance

Regular inspection: Regularly check the sealing, smooth rotation and transmission quality of the electrical signal of the slip ring.

Cleaning and maintenance: Clean the surface and interior of the slip ring regularly to remove impurities such as oil and dust, and keep the slip ring clean and dry.

Lubrication treatment: Lubricate the slip ring regularly according to the use of the equipment to ensure smooth rotation of the slip ring.

Replace damaged parts: If the seals, conductive rings and other parts of the slip ring are found to be damaged, they should be replaced in time to avoid affecting the transmission quality and service life.

Precautions

Avoid impact: Avoid impact and falling during transportation and storage to avoid damage to the interface and internal parts.

Anti-loosening treatment: The bolts used for installation and fixing need to be anti-loosening treatment to ensure that the slip ring will not loosen during rotation.

Thread correspondence: When installing the threaded rotary joint, pay attention to whether the thread direction of the inner and outer tubes corresponds to the rotation direction of the drum, and the thread rotation direction of the inner and outer tubes should also be consistent.

Filter medium: The transmission medium must be filtered before entering the slip ring and no impurities should be present to ensure the service life of the slip ring.

Support and anti-rotation: The support and anti-rotation of the rotary joint should be appropriate. Generally, the anti-rotation rod and the fixed part should maintain a certain degree of freedom. Customers can install it independently according to the application environment.

Summary

Electrical Rotary Joint, as a device that integrates electrical signal and fluid medium transmission, has the characteristics of medium diversity, compact structure, signal integration, customized service and high performance. It is widely used in industrial automation equipment, packaging equipment, SMT equipment, testing equipment and robots. In terms of installation and maintenance, certain installation instructions and precautions need to be followed to ensure the normal operation and service life of the slip ring. Through reasonable installation and maintenance, the stability and reliability of the equipment can be improved, the failure rate can be reduced, and strong support can be provided for the production and development of the enterprise.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions