Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2024-12-26 09:49:16

Reehonde is a Custom Conductive Slip Ring Supplier. We have a full set of processing equipment and a strong technical R&D team, and are committed to providing customers with high-quality, innovative and customized products. Conductive Slip Rings are widely used in various rotating equipment that need to transmit power and signals. Reehonde has been able to meet the diverse needs of different industries for slip ring products through years of technical accumulation and practical experience.

What is a Conductive Slip Ring?

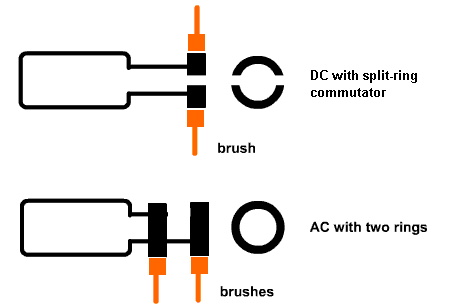

A conductive slip ring, also known as an electrical rotary joint, is a device that allows power or signals to be transmitted during a rotating motion. It is mainly composed of a stationary part and a rotating part. The stationary part usually contains brushes (or brushes), and the rotating part contains a conductive ring. Through the contact between these components, the slip ring can stably transmit power and signals during rotation, and is commonly used in rotating platforms, robots, sensors, generators, automation equipment and other fields.

Processing machines and processes for conductive Slip Rings

Reehonde has a full set of advanced processing equipment and is equipped with a professional technical R&D team. These equipment include high-precision CNC machine tools, laser cutting machines, automated assembly lines, and high-precision testing instruments to ensure that every detail of the conductive slip ring can be precisely controlled.

Main processing equipment:

CNC machine tools: used to process the shell, conductive ring and other parts of the conductive slip ring to ensure strict control of accuracy and size.

Laser cutting machine: used for precision cutting materials, especially suitable for processing special materials.

Automated assembly line: improve production efficiency and ensure the assembly quality of each slip ring.

High-precision testing instruments: used to test the electrical and mechanical properties of the slip ring to ensure compliance with industry standards.

Processing technology:

Material selection and preparation: select suitable metal materials (such as stainless steel, copper alloy, etc.) and insulating materials according to customer needs. The materials are strictly screened and processed to ensure that they have sufficient conductivity and mechanical strength.

Mechanical processing: use CNC lathes, milling machines and other equipment to process the basic shape of the slip ring to ensure dimensional accuracy.

Assembly of brushes and conductive rings: accurately match the brushes and conductive rings to ensure the stable transmission performance of the slip ring.

Insulation treatment: insulate the inside of the slip ring to prevent electrical contact problems and ensure the stability of signal transmission.

Testing and debugging: After each production link, strict electrical and mechanical performance tests are carried out to ensure the stability and durability of the slip ring.

Technical parameters and specifications of conductive slip rings

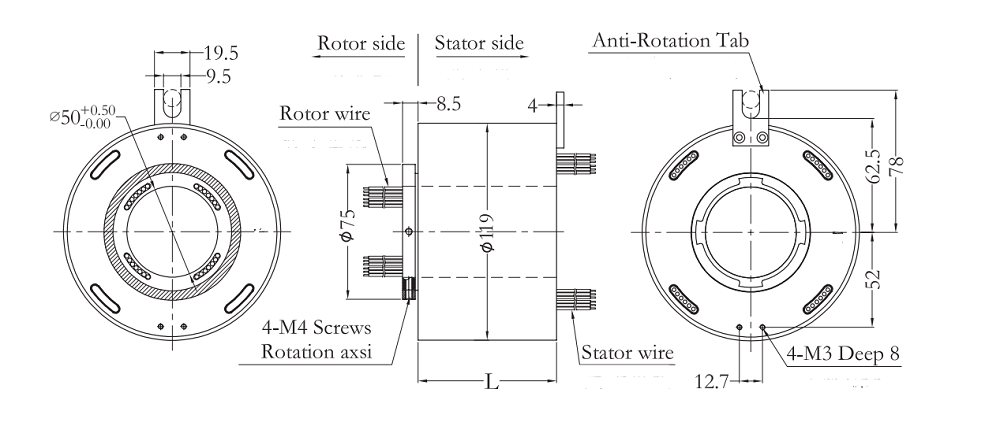

Size and accuracy:

Outer diameter: It can be customized according to customer needs, from 20mm to more than 500mm, to meet the space requirements of different equipment.

Accuracy: The axial accuracy is ±0.01mm and the radial accuracy is ±0.02mm, ensuring the precise installation and stable operation of the slip ring.

Rotation speed: It can support a maximum speed of 500 rpm (revolutions per minute), and special designs can reach 2000 rpm.

Contact resistance: The contact resistance of the conductive slip ring can be controlled at < 10 mΩ, ensuring stable power and signal transmission.

Current capacity: The maximum current of a single channel is 10A, and it supports multi-channel design and supports a maximum current transmission of 100A.

Signal bandwidth: The high-frequency signal transmission capability can reach 1 GHz, which is suitable for high-speed data transmission occasions.

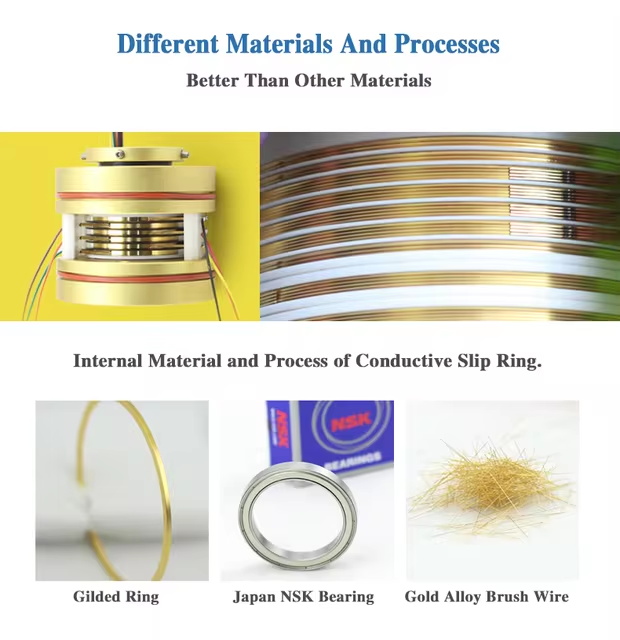

Material:

Stainless steel: Highly corrosion-resistant 316L stainless steel is used to improve the durability and corrosion resistance of the slip ring, especially suitable for marine, chemical, food processing and other industries.

Copper alloy: The conductive ring inside the slip ring is made of C10100 copper alloy, which has excellent conductivity and ensures stable signal transmission.

Special alloys: For extreme environments (such as high temperature, strong corrosion, radiation, etc.), special alloy materials (such as titanium alloy, aluminum alloy, etc.) can be used to meet the needs of different industrial fields.

Brush material: High-quality metal brush materials such as silver alloy brushes and copper alloy brushes are used, which have excellent conductivity, wear resistance and long life.

Electrical performance:

Voltage range: The standard voltage is 250VAC, 480VAC, and the special design can support high voltage working environments such as 600VAC, 1000VDC.

Current type: Supports the transmission of direct current (DC) and alternating current (AC) current to meet the needs of different types of equipment.

Electrical isolation: Supports multi-channel electrical isolation to avoid electrical interference and ensure safe and stable transmission of signals and power.

Processing technology and machine precision

Processing precision:

CNC machine tool precision: Using high-precision CNC lathes and milling machines, the machine tool precision reaches ±0.005mm. All machined parts of the slip rings are strictly checked for size and shape to ensure high precision and consistency.

Laser cutting accuracy: The cutting accuracy of the laser cutting machine is ±0.002mm, which can accurately process complex graphics and micro holes.

Surface treatment: All metal surfaces are precisely polished, and the surface roughness is controlled below Ra 0.2µm to ensure better contact between the conductive ring and the brush, reducing friction and wear.

Testing and verification:

Electrical test: Each conductive slip ring will undergo strict electrical testing before leaving the factory to ensure that there is no leakage and poor contact. Common test items include contact resistance, current carrying capacity, voltage resistance, etc.

Mechanical performance test: The rotating part of the slip ring will undergo a high-load rotation test to test the speed, durability and friction coefficient. All slip rings are subjected to at least 5,000 dynamic rotation tests to ensure their long-term stable operation.

Environmental testing: The slip rings are subjected to environmental tests such as high and low temperature, humidity, and salt spray to ensure that they can operate reliably in extreme environments.

Application optimization and features of conductive slip rings

Low friction and low noise:

Silver alloy brushes and special coating materials are used to reduce friction with conductive rings. This not only prolongs the service life of brushes and conductive rings, but also effectively reduces the noise of the equipment, which is suitable for environments with strict noise requirements, such as medical equipment, aerospace and other fields.

High-frequency signal transmission:

In high-speed rotation occasions, Reehonde's conductive slip rings adopt an optimized design to support the transmission of high-frequency signals with a maximum bandwidth of up to 1 GHz. This design is particularly suitable for equipment that requires high-frequency signal transmission, such as radar systems, communication equipment and high-precision instruments.

High current carrying capacity:

According to customer needs, Reehonde can provide customized slip rings with high current carrying capacity, up to 100A per channel. This makes the slip rings suitable for power systems, heavy machinery and large industrial equipment.

High temperature and corrosion resistant design:

The housing and brush parts of the slip ring are made of high-temperature resistant materials (such as ceramic coatings) and can withstand operating temperatures up to 200°C. It is particularly suitable for work in high-temperature environments, such as steelmaking, petrochemical and other industries.

Using anti-corrosion materials and special coatings, it can operate stably for a long time in strong acid and alkali environments, and is suitable for harsh environments such as chemical and marine.

Application scenarios

Robotics:

In industrial robots, Reehonde's customized slip rings can ensure the power supply and signal transmission of robot joints. Through optimized design, the slip rings provided by Reehonde can support current transmission up to 100A, ensuring the efficient operation of the robot arm. At the same time, the low friction design reduces noise and vibration during the operation of the robot arm.

Wind power generation:

In wind turbines, slip rings are used to transmit power and control signals of the generator. Reehonde's high current carrying capacity and high temperature resistant design enable it to operate stably in extreme environments, with a maximum carrying current of 100A and can adapt to ambient temperatures of up to 150°C.

Medical equipment:

In CT scanners and MRI equipment, Reehonde's conductive slip rings can transmit power and data during high-speed rotation. Its high-frequency signal transmission capability (1 GHz) ensures the stability of device data transmission, while the low noise and low friction design ensure the accuracy and durability of the equipment.

Defense and Aerospace:

In satellites and spacecraft, Reehonde's Custom Slip Rings ensure power and signal transmission for critical sensors and communication devices in rotating platforms. The use of lightweight, high-temperature resistant special materials such as titanium alloys allows these slip rings to work properly in extreme temperature and radiation environments.

Automated production lines:

In automated production lines, Reehonde's slip rings are widely used to transmit power and signals, supporting rotation speeds up to 2000 rpm. Its compact design allows the slip rings to operate efficiently in limited spaces, suitable for the application requirements of various automated equipment.

Reehonde's custom conductive slip rings are widely used in multiple industries with their precision processing technology, high-performance material selection and strict quality control. Whether in terms of mechanical accuracy, electrical performance, environmental adaptability or service life, Reehonde's conductive slip rings can provide customers with customized solutions to meet high-standard application requirements.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions