Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2024-12-10 15:41:36

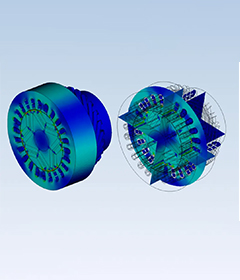

In industries where reliable and continuous power or data transmission is essential, slip rings are key components. Used in rotating machinery and equipment, these devices allow electrical signals or power to transfer between stationary and rotating parts without physical connection. As the demand for high-performance, custom-designed slip rings increases, so does the need for precise design processes. One of the most effective tools in ensuring the performance and reliability of custom electrical slip rings is electromagnetic simulation.

The Role of Electromagnetic Simulation in Slip Ring Design

Before embarking on the manufacturing process, it’s critical to ensure that a slip ring will function as required under real-world conditions. Electromagnetic simulation plays a significant role in this process by allowing engineers to model the behavior of the slip ring’s electrical fields, material properties, and interactions before any physical prototype is created.

Simulation tools like ANSYS Maxwell, CST STUDIO SUITE, and FEKO are widely used in the industry to simulate electromagnetic fields and optimize designs for rotary slip rings. These software solutions help engineers understand key factors such as the distribution of electromagnetic fields, the electrical conductivity of materials, and the impact of various geometries on the system’s performance.

Step 1: Theoretical Analysis for Custom Slip Rings

The first step in designing a custom slip ring is conducting a theoretical analysis of the system. This involves understanding the basic operating principles of the slip ring, including how it will interact with the rotating system. By identifying potential challenges—such as power loss, signal interference, or heat buildup—engineers can define the goals and requirements for the electromagnetic simulation.

Step 2: Creating an Accurate Model for Electromagnetic Simulation

Once the theoretical groundwork is laid, the next step is to create a model using simulation software. An accurate model is critical in achieving reliable results. This involves building a geometric representation of the slip ring, based on the design specifications, and ensuring that the materials used for the Rotary Slip Ring are correctly represented within the simulation. Materials such as copper or gold, known for their excellent conductivity, may be selected for specific applications, while special coatings or insulation materials can be chosen to enhance the performance under harsh environmental conditions, like high temperatures or vibration.

Step 3: Setting Simulation Parameters for Performance Optimization

Simulation parameters need to be carefully configured to ensure accurate results. These include:

Boundary conditions: Defining how the electromagnetic fields will interact with the boundaries of the system, such as the rotating shaft or external casing.

Excitation sources: Identifying how the power or data will be transferred across the slip ring, such as applying current or voltage sources in the model.

Operating frequency: For electrical slip rings that are designed to transmit high-frequency signals or power, it's essential to simulate how the system behaves across different frequencies and identify potential resonance or interference issues.

By setting appropriate simulation parameters, engineers can predict the performance of the slip ring, ensuring that the Rotary Slip Ring design will meet the required specifications for power or data transmission without disruptions.

Step 4: Mesh Generation and Simulation Solver Settings

Once the model is set up, it is divided into smaller elements or "meshes," which allows for numerical calculations of electromagnetic interactions. The accuracy of the mesh is critical, as it determines how precise the results will be. A finer mesh often leads to more accurate simulations but at the cost of increased computational time. Therefore, optimizing mesh resolution is a key step in balancing computational efficiency and accuracy.

Additionally, simulation solver settings, such as the number of iterations and convergence criteria, must be carefully adjusted. These factors affect the stability and reliability of the simulation, ensuring that results are both stable and accurate.

Step 5: Post-Simulation Analysis and Optimization

After the simulation is run, the results are analyzed to assess the slip ring’s performance. Key outputs might include the distribution of electromagnetic fields, power losses, and the effectiveness of insulation. By reviewing these results, engineers can determine if the slip ring design meets the required performance standards. If discrepancies or weaknesses are identified, the design can be iteratively adjusted.

For instance, if the simulation reveals high power loss or inefficient signal transmission, engineers can modify parameters such as the material selection, geometry, or insulation, and re-run the simulation to assess improvements.

Step 6: Continuous Optimization for Custom Slip Rings

One of the biggest advantages of using electromagnetic simulation in electrical slip ring design is the ability to continuously optimize the design. Based on simulation results, engineers can adjust key parameters—such as geometry, materials, or operating conditions—to meet customer-specific needs. Whether designing slip rings for harsh environments, such as high temperatures or extreme vibrations, or for specialized applications like high-speed data transmission, simulations allow for rapid testing and validation.

In addition to optimizing for performance, engineers can use simulations to assess the slip ring’s reliability, durability, and efficiency, ensuring that it will function effectively over the long term in real-world applications.

Conclusion: The Future of Custom Slip Rings

At Reehonde, we specialize in designing and manufacturing custom slip rings that meet the exact needs of our clients. By leveraging the power of electromagnetic simulation, we are able to provide solutions that guarantee performance, reliability, and durability, regardless of the complexity of the application. Whether you require a rotary slip ring for industrial automation, robotics, or renewable energy systems, simulation ensures that every design is optimized for maximum efficiency.

Electromagnetic simulation has become an invaluable tool in the development of custom electrical slip rings, allowing engineers to predict and enhance the performance of slip rings before physical production. This not only reduces development time and costs but also ensures that the final product meets the high standards required by industries relying on precision and reliability.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions