Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2024-12-10 17:00:57

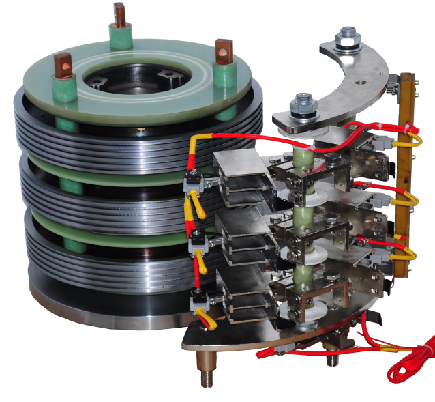

When designing and manufacturing conductive Slip Rings, material selection plays a critical role in determining the performance, reliability, and longevity of the slip ring. Conductive Slip Rings are used in a variety of industries, from industrial automation to aerospace, and choosing the right materials ensures they meet the demanding requirements of these applications. This blog will explore the key materials used in the production of conductive Slip Rings, their functions, and how they contribute to the overall quality of the product.

Conductive Brushes

The brushes in a slip ring are responsible for maintaining electrical contact with the rotating part, allowing the transmission of electrical signals or power. The material of these brushes significantly impacts the conductivity, durability, and noise levels of the slip ring system.

Copper: Copper is the most commonly used material for conductive brushes due to its excellent electrical conductivity. Copper brushes are effective in low and medium-power applications where high precision and low wear are essential. However, copper can suffer from rapid wear when used in high-speed operations.

Silver-Carbon: For high-performance applications, silver-carbon brushes are often preferred. The silver content provides superior conductivity, while the carbon helps to reduce wear and friction. These brushes are ideal for high-speed operations and environments requiring minimal electrical noise.

Gold-Plated Brushes: In specialized applications such as aerospace or military-grade systems, gold-plated brushes may be used. Gold offers excellent corrosion resistance and a low contact resistance, which is crucial for maintaining long-term reliability in harsh environments.

Conductive Rings (Rotor and Stator)

The conductive rings in a slip ring system provide the interface for the brushes to make contact. The material selection for these rings affects both the electrical performance and the mechanical strength of the slip ring.

Copper-Alloy: Copper alloys are often used for conductive rings due to their high electrical conductivity and good mechanical properties. They are durable and capable of withstanding high mechanical stresses and electrical loads, making them ideal for industrial applications.

Silver-Coated Copper: In applications where higher conductivity is required, silver-coated copper rings are often used. The silver coating improves conductivity, making it an excellent choice for systems that need to transfer large amounts of power or high-frequency signals.

Gold-Plated Copper: Similar to the use of gold-plated brushes, gold-plated copper rings are used in systems where corrosion resistance and low contact resistance are critical. These are often found in highly sensitive or high-reliability applications, such as medical or military equipment.

Insulating Materials

The insulating materials used in a slip ring assembly are crucial for ensuring the electrical signals do not interfere with each other and that the slip ring functions safely and efficiently. These materials need to withstand high temperatures, humidity, and mechanical stresses.

PBT (Polybutylene Terephthalate): PBT is a popular insulating material due to its high strength, resistance to heat, and chemical stability. It is often used in the housing of slip rings where insulation is needed between the conductive rings.

PTFE (Polytetrafluoroethylene): PTFE, commonly known as Teflon, is widely used in the construction of slip rings because of its excellent electrical insulating properties and resistance to high temperatures. PTFE is ideal for systems operating in extreme conditions.

Ceramics: In high-voltage applications, ceramics may be used for insulating materials. Ceramics provide exceptional electrical insulation properties and are highly resistant to temperature fluctuations, making them suitable for specialized industries like aerospace or defense.

Bearings

The bearings in a slip ring system support the rotating parts and ensure smooth motion. The choice of material for bearings is crucial for reducing friction, extending the lifespan of the slip ring, and ensuring smooth operation.

Bronze: Bronze is a popular choice for bearings because it offers low friction, high wear resistance, and excellent mechanical strength. It is commonly used in industrial slip ring systems where durability is a key concern.

Stainless Steel: For applications that require corrosion resistance or need to operate in challenging environments, stainless steel bearings are used. Stainless steel has a high resistance to rust and corrosion, making it ideal for marine or outdoor applications.

Ceramic Bearings: In high-performance applications where extreme precision and low friction are necessary, ceramic bearings may be used. They offer superior wear resistance and can operate at high speeds with minimal friction.

Seals and Protection

In many applications, slip rings are exposed to harsh environmental conditions such as moisture, dust, and chemicals. Proper sealing materials are essential to protect the internal components from external damage and ensure consistent performance over time.

Rubber Seals: Rubber seals are commonly used to protect slip rings from dust and moisture. They offer good flexibility and a tight seal, preventing contaminants from entering the system.

O-Rings: O-rings made from elastomers such as nitrile or silicone are also used for sealing slip rings. These seals provide a secure barrier against dust, moisture, and chemicals, ensuring the system remains functional even in adverse conditions.

Conclusion

Material selection is one of the most important aspects of designing and manufacturing Conductive Slip Rings. Each component, from brushes to bearings, plays a vital role in ensuring the slip ring operates efficiently and reliably. By carefully selecting materials based on conductivity, wear resistance, temperature tolerance, and environmental protection, manufacturers can create slip rings that meet the demands of various industries. Whether for industrial automation, military applications, or renewable energy systems, the right materials ensure that slip rings continue to perform optimally for years to come.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions