Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

Inductive Slip Ring

Inductive Slip Rings are advanced devices that facilitate the transfer of signals and power across rotating interfaces. They typically consist of a stationary part, known as the stator, and a rotating part, known as the rotor. The stator and rotor are equipped with induction coils that allow for the non-contact transmission of data and power, enabling seamless communication and functionality in rotating applications.

The core principle of Inductive Slip Rings lies in electromagnetic induction. When an alternating current passes through the coils on the stator, it creates a magnetic field. This magnetic field induces an electrical current in the coils on the rotor, effectively transmitting signals and power without physical contact. This non-contact design eliminates the wear and tear associated with traditional mechanical slip rings, significantly enhancing reliability and lifespan.

One of the key advantages of Inductive Slip Rings is their ability to handle high-speed rotations while maintaining stable and reliable signal transmission. Unlike mechanical slip rings, which can experience wear and signal degradation over time, inductive slip rings offer consistent performance even at high speeds. This makes them ideal for applications requiring continuous rotation and reliable data transfer, such as in robotic systems, aerospace equipment, and industrial machinery.

Inductive Slip Rings have a wide range of applications across various industries. In the aerospace sector, they are used in gimbal systems, flight control surfaces, and other rotating components to transmit critical flight data. In robotics, they enable seamless communication between rotating parts, such as joints and actuators, allowing for precise and responsive movements. Industrial machinery, such as wind turbines and heavy-duty equipment, also benefit from inductive slip rings, as they facilitate reliable data transmission and control in rotating environments.

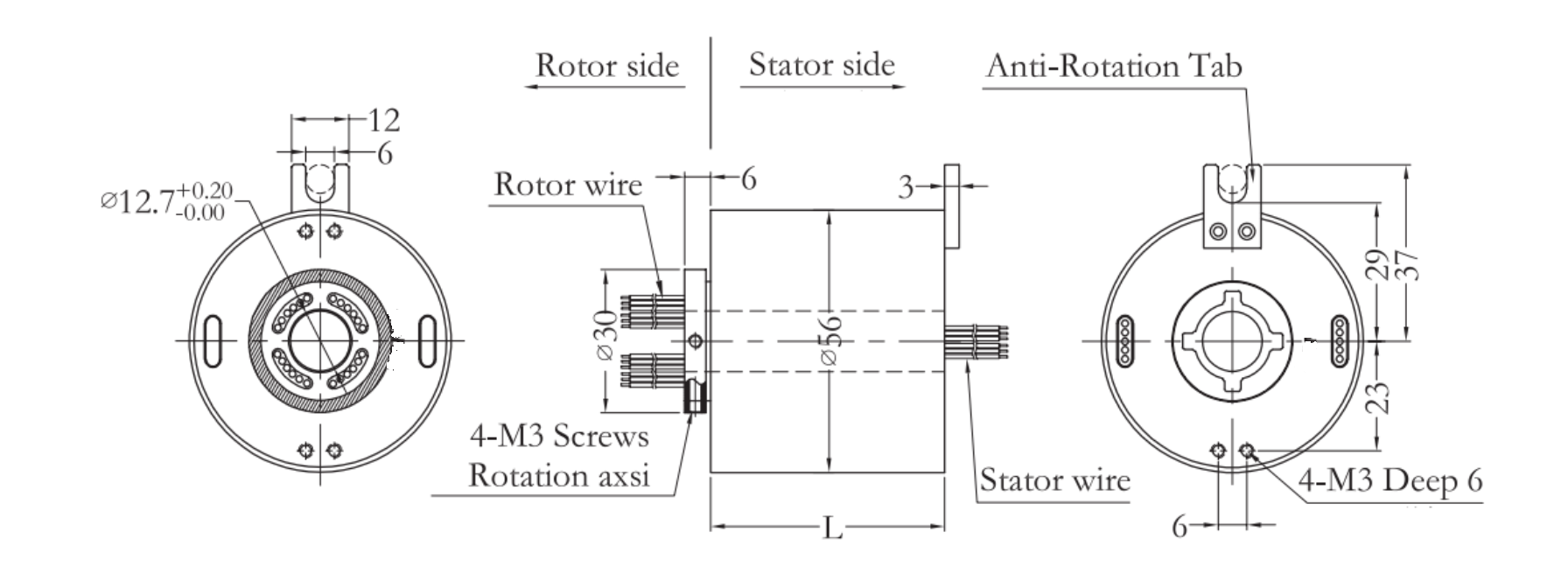

Product Drawings

Inductive Slip Ring Technology

Inductive Slip Ring Technology represents a significant advancement in the field of rotating electrical connections. It leverages the principles of electromagnetic induction to create a robust and reliable system for transmitting signals and power across rotating interfaces. This technology eliminates the need for physical brushes or contacts, thereby reducing wear and tear, minimizing maintenance requirements, and enhancing overall system reliability.

Inductive Slip Rings are characterized by their high-speed capabilities, excellent signal integrity, and wide operating temperature ranges. They can handle a variety of signal types, including analog, digital, and high-frequency signals, making them versatile solutions for diverse applications. Additionally, their compact design and lightweight construction make them suitable for integration into space-constrained and weight-sensitive systems.

Inductive Slip Ring Components

The components of Inductive Slip Rings are precision-engineered to ensure optimal performance. The stator and rotor are typically made of high-quality materials, such as laminated steel or aluminum, to provide a stable platform for the induction coils. The coils are made of fine copper wire and are precisely wound to ensure consistent inductance and minimize electrical noise.

The design of Inductive Slip Rings also incorporates shielding and grounding techniques to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). This ensures that the transmitted signals remain clear and uncorrupted, even in environments with high levels of electrical noise.

Inductive Slip Ring Applications

Inductive Slip Rings are widely used in a variety of applications that require reliable data transmission and power transfer across rotating interfaces. In the aerospace industry, they are essential components in flight control systems, gyro-stabilized platforms, and other critical systems that require high-precision and reliability. Robotics and automation also benefit from inductive slip rings, as they enable seamless communication between rotating parts, enhancing the precision and responsiveness of robotic systems.

In addition, Inductive Slip Rings are used in industrial machinery, such as wind turbines, cranes, and other heavy-duty equipment, to facilitate reliable data transmission and control in rotating environments. Their compact design and high-speed capabilities make them ideal solutions for applications where space is limited and performance is critical.

Inductive Slip Ring Systems

Inductive Slip Ring Systems refer to complete assemblies that incorporate inductive slip rings along with necessary accessories and components. These systems are designed to provide turnkey solutions for applications requiring rotating electrical connections. They typically include the stator, rotor, mounting hardware, connectors, and any other required components to facilitate easy integration into existing systems.

Inductive Slip Ring Systems offer numerous advantages, including reduced maintenance, enhanced reliability, and improved signal integrity. They are designed to meet the specific requirements of diverse applications, ensuring optimal performance and long-term durability. With their ability to handle high-speed rotations, transmit a variety of signal types, and operate in harsh environments, inductive slip ring systems are becoming increasingly popular solutions for applications requiring reliable rotating electrical connections.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions