Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

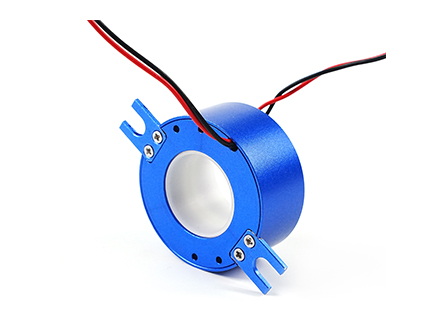

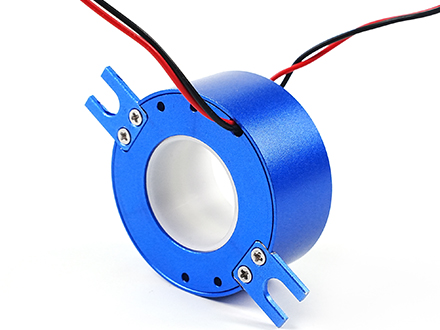

Definition

Through Bore Slip Ring, also known as through-hole conductive slip ring, is a special electrical connection device used to transmit electrical signals, power, or data between rotating and fixed components. It allows the rotating shaft to pass through through a central through-hole while maintaining continuous signal transmission without entanglement or breakage.

Characteristics

Efficient transmission: Through Bore Slip Ring is designed for data transmission in high-speed applications, meeting users' needs for reliable data transmission solutions.

Multipath capability: With multiple circuits, it can transmit multiple signals simultaneously, providing a convenient solution for applications that require multiple data paths.

Durable and Reliable: Certified by CE and RoHS, it meets international safety and environmental standards, ensuring users' confidence in choosing reliable components.

Wide operating temperature range: capable of operating within a wide temperature range of -30 ° C to+80 ° C, suitable for various environmental conditions.

High current capacity: With a maximum current capacity of up to 10A and a rated voltage of 440VAC/VDC, it can handle high-power applications.

Function

Signal transmission: allows continuous transmission of electrical signals such as audio, video, data, etc. between rotating and fixed components.

Power transmission: It can transmit electricity and provide the necessary power supply for rotating components.

Data Communication: Supports high-speed data transmission and is suitable for application scenarios that require real-time data exchange.

Application Fields

Aerospace: Used in aircraft, satellites, and other aerospace vehicles to transmit control signals and data, ensuring flight safety and stability.

Military equipment: Used in military equipment such as tanks and armored vehicles to transmit signals and data from systems such as radar and communication.

Industrial automation: Used in industrial automation equipment such as robots and automated production lines to transmit control signals and power, achieving automated production.

Medical equipment: Used in medical devices such as CT machines and MRI machines to transmit image data and control signals, ensuring the normal operation of medical equipment.

Security monitoring: Used in security monitoring equipment such as camera gimbals to transmit video signals and control signals, achieving all-round monitoring.

Maintenance and upkeep

Regular inspection: Regularly inspect the Through Bore Slip Ring, including appearance, connection lines, transmission performance, etc., to ensure the normal operation of the slip ring.

Cleaning and maintenance: Use a clean cloth or tissue to gently wipe the surface of the slip ring to remove dust and dirt. Avoid using corrosive cleaning agents or tools to prevent damage to the slip ring surface.

Lubrication treatment: Apply an appropriate amount of lubricant on the rotating parts of the slip ring to reduce friction and wear, and extend the service life of the slip ring.

Avoid overload: During use, avoid exceeding the rated current and voltage range of the slip ring to prevent damage to the internal circuits and components of the slip ring.

Pollution prevention: Ensure the cleanliness of the environment around the slip ring, and prevent pollutants such as water and chemicals from entering the interior of the slip ring, causing short circuits or damage to the circuit.

Precautions

Installation requirements: When installing the Through Bore Slip Ring, ensure the coaxiality between the rotating and fixed components to avoid excessive radial and axial runout. At the same time, specialized tools should be used for installation to avoid damaging the circuits and components inside the slip ring.

Usage environment: The slip ring should be used within the specified temperature range to avoid excessive or insufficient temperature affecting the performance of the slip ring. At the same time, slip rings should be avoided from being used in damp, corrosive, or flammable environments.

Operating standards: During the operation process, relevant operating standards and safety requirements should be followed to avoid damage to the slip ring or causing safety accidents. For example, when plugging or unplugging cables, ensure that the power is turned off to avoid the risk of electric shock or short circuit.

Maintenance: Regularly maintain the slip ring, including cleaning, lubrication, inspection, and other aspects. During maintenance, it is important to avoid using corrosive cleaning agents or tools to prevent damage to the surface and internal circuits of the slip ring.

Replacement cycle: Develop a reasonable replacement cycle based on the usage and lifespan requirements of the slip ring. When replacing the slip ring, a slip ring that matches the prototype number should be selected to ensure transmission performance and reliability.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions