Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

Definition

Conductive Slip Ring, commonly known as conductive slip ring or collector ring, is a special electrical connection device used to transmit electrical energy or signals between rotating parts and fixed parts. It allows current or signals to be transmitted uninterruptedly during rotation, thus avoiding the entanglement or breakage problems that may occur in traditional cables or wires during rotation.

Features

Precious metal brush cluster multi-point contact: The conductive slip ring adopts a precious metal brush cluster multi-point contact design, which not only ensures good conductivity, but also makes the friction extremely low, reducing wear and energy loss.

Ultra-low torque, low loss: The torque generated by the conductive slip ring during rotation is extremely low, which means that it can achieve rotation with less force, thereby reducing energy loss and improving the operating efficiency of the equipment.

High stability: Due to the use of advanced manufacturing processes and materials, the conductive slip ring can still maintain stable performance under long-term operation and is not prone to malfunction or failure.

Long life (up to 2000w rotation): The conductive slip ring has a long life and can withstand up to 20 million rotations, which greatly reduces the maintenance cost of the equipment and improves the reliability and durability of the equipment.

However, there are some limitations of conductive slip rings, such as relatively low transmission efficiency (although it has been significantly improved through optimized design and material selection), certain energy loss (although the ultra-low torque design has reduced this part of the loss), and wear of brushes and contacts that will affect its service life (although the precious metal cluster brush design and long life characteristics have extended the service life), but these problems do not affect the wide application of conductive slip rings in rotating equipment.

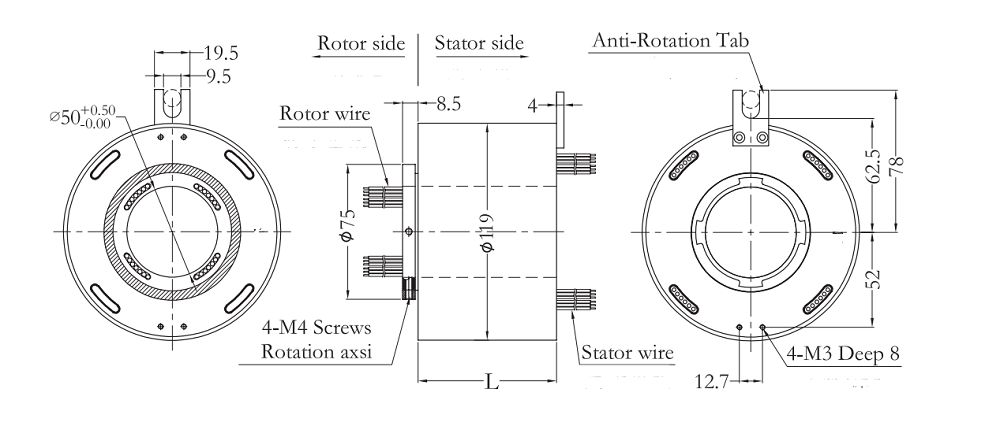

Drawings

Function

The basic function of conductive slip rings is to achieve continuous transmission of electrical energy or signals between rotating parts and fixed parts. This device is widely used in various mechanical equipment that requires rotating power supply or signal transmission. Its main function is to achieve electrical connection between rotating parts and fixed parts to ensure that rotating equipment can continuously receive electrical energy and signals during operation.

Application Field

Conductive slip rings are widely used in various occasions that require rotating power supply or signal transmission, including but not limited to the following fields:

Wind power generation: In wind power generation systems, conductive slip rings are used to transmit electrical energy and signals in wind energy conversion systems to ensure the normal operation of wind turbines.

Medical equipment: In rotating equipment such as CT scanners and operating tables, conductive slip rings are used to transmit electrical energy and signals when X-ray tubes or surgical instruments rotate.

Aerospace: In the field of aerospace, conductive slip rings are used to transmit various flight parameters and signals to ensure the safety and stable operation of aircraft.

Automated machinery: In automated mechanical equipment, conductive slip rings are used to achieve electrical connection between rotating parts and fixed parts, improving the automation level and production efficiency of equipment.

In addition, conductive slip rings are also used in resistance cutting machines, intelligent dynamic toys, horizontal copper plating production lines, smart home appliances, rotating stages, single crystal furnaces, cable reels, reactors, circular knitting machines, glucose filling production equipment, dyeing equipment, liquid medicine filling equipment, robotic arms, beer production equipment, rotating light boxes, dairy production equipment, surgical lights, drilling equipment and other fields.

Maintenance and Care

Regular maintenance and care of conductive slip rings is the key to ensure their long-term stable operation. The following are some suggestions for maintenance and care:

Clean the surface and brush head of the slip ring: Regularly clean the surface and brush head of the conductive slip ring to remove accumulated dust and dirt and maintain its good conductivity.

Check the wear of the brush head: Check the wear of the brush head regularly. If the wear is serious, replace the new brush head in time to avoid affecting the transmission efficiency and life of the conductive slip ring.

Check the electrical connection and fixed parts: Check the electrical connection and the fastening of the fixed parts of the conductive slip ring regularly to ensure that the connection is reliable and stable.

Keep the working environment of the equipment clean and dry: Avoid dust and moisture from damaging the conductive slip ring, and keep the working environment of the equipment clean and dry.

Precautions

When using and maintaining the conductive slip ring, pay attention to the following matters:

Professional maintenance personnel: The conductive slip ring should be disassembled and cleaned by professional maintenance personnel. General personnel should not attempt to disassemble it to avoid damaging the equipment or causing safety hazards.

Cleaning agent selection: The cleaning agent should be able to dissolve the grease formed by light oil, dissolve the carbon deposits and fat dirt formed by the arc, etc., and have strong volatility. At the same time, the cleaning agent cannot corrode the metal, and cannot cause rubber or plastic to age or crack.

Lubricant selection: The lubricant should be evenly distributed on the surface of the conductive ring, reduce the friction resistance between the ring and the brush needle contact surface, reduce wear, and prevent oxidation and corrosion of the ring and brush needle. In addition, the viscosity of the lubricant should be insensitive to temperature changes, the viscosity does not increase significantly at low temperatures, and does not volatilize at high temperatures.

Avoid excessive wear: During use, excessive wear of the brushes and contacts of the conductive slip ring should be avoided to extend its service life.

Regular inspection: The conductive slip ring should be inspected and maintained regularly to ensure its normal operation and safety.

Correct installation: When installing the conductive slip ring, the coaxiality between its fixed parts and rotating parts should be ensured to reduce vibration and wear. At the same time, pay attention to the safety and reliability of the electrical connection to ensure the correct transmission of current and signals.

In summary, as a special electrical connection device, the conductive slip ring plays an important role in rotating equipment. Understanding its definition, characteristics, functions, application areas, and maintenance and maintenance methods is of great significance to ensure the normal operation of the equipment and extend its service life. At the same time, relevant matters need to be paid attention to during use to ensure its safety and reliability. With the continuous advancement of science and technology and the continuous expansion of application fields, the conductive slip ring technology will continue to develop and improve, providing more efficient and reliable solutions for the design and operation of rotating equipment.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions