Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

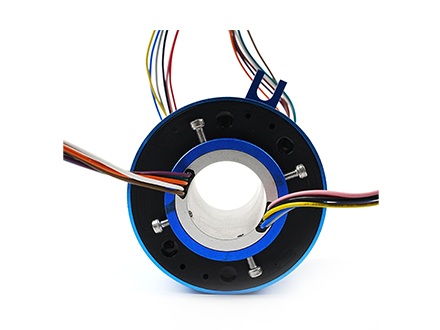

Product Description

Power Slip Ring is a special electrical connection device, also known as a conductive slip ring, collector ring or collector ring. It is mainly used to transmit electrical energy or signals between rotating parts and fixed parts, ensuring uninterrupted transmission of current or signals during rotation.

This design avoids the problem of entanglement or breakage of traditional cables or wires during rotation, allowing rotating equipment to continuously supply power or transmit signals.

Product Features

Structure: Power Slip Ring usually consists of a rotatable outer ring and a fixed inner ring, and realizes continuous transmission of current through a series of metal contacts and brushes. The brush is usually made of carbon material, which has good conductivity and wear resistance, and can maintain stable contact when rubbing against the contact.

Working Principle: When the outer ring rotates, the inner ring remains fixed, and the metal contact between the two realizes the transmission of current through the brush. As the outer ring rotates, continuous sliding contact occurs between the contact and the brush, thereby ensuring continuous transmission of current.

Flexibility: Power Slip Ring allows rotating parts to rotate freely without worrying about cable entanglement, which improves the flexibility of the equipment.

Reliability: Through optimized contact and conductive material selection, it provides stable current and signal transmission, enhancing the reliability of the equipment.

Convenient maintenance: Some Power Slip Rings support replaceable brushes and contacts for easy maintenance.

Transmission efficiency and life: Compared with traditional cable connections, the transmission efficiency of Power Slip Ring may be slightly lower, and there is a certain amount of energy loss. At the same time, the wear of brushes and contacts will affect its life, and regular maintenance and replacement are required.

Function of Power Slip Ring

The main function of Power Slip Ring is to transmit power or signals between rotating parts and fixed parts to ensure the normal operation of rotating equipment. It allows current or signals to be transmitted uninterruptedly during rotation, thereby avoiding the problem of winding or breaking that may occur in traditional cables or wires during rotation. This design enables Power Slip Ring to continuously supply power or transmit signals in rotating equipment, improving the performance and reliability of the equipment.

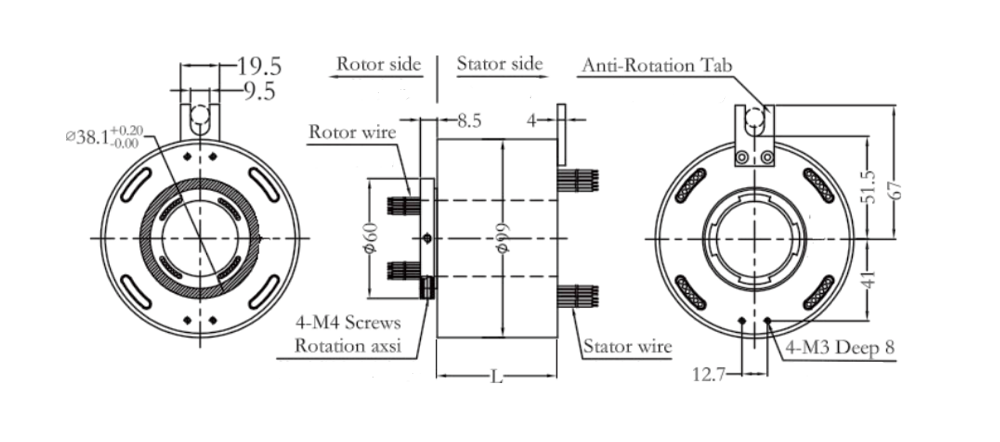

Product Drawings

Application field

Power Slip Ring is widely used in various occasions that require rotating power supply or signal transmission, including but not limited to the following fields:

Wind power generation: In wind power generation, Power Slip Ring is used to transmit power and signals in wind energy conversion systems to ensure the normal operation of wind turbines.

Medical equipment: In medical equipment such as CT scanners and operating tables, Power Slip Ring is used to transmit power and signals when X-ray tubes or surgical instruments rotate.

Aerospace: In the field of aerospace, Power Slip Ring is used to transmit power and signals during the rotation of aircraft to ensure the normal operation and communication of aircraft.

Automated machinery: In automated mechanical equipment, Power Slip Ring is used to achieve electrical connection between rotating parts and fixed parts to improve the flexibility and reliability of equipment.

Camera pan/tilt: In the camera pan/tilt, Power Slip Ring is used to transmit the power and signals of the camera to ensure that the camera can continue to shoot and transmit images during rotation.

Rotating platform: In the rotating platform, Power Slip Ring is used to transmit the power and signals of the platform to ensure that the platform can operate and communicate normally during rotation.

Maintenance and care

Regular maintenance and care of Power Slip Ring is the key to ensure its long-term stable operation. Maintenance content includes the following aspects:

Cleaning the surface of the slip ring and the brush head: Regularly clean the dust and dirt on the surface of the slip ring and the brush head to keep it clean and dry.

Check the wear of the brush head: Check the wear of the brush head regularly, and replace the severely worn brush head in time to avoid affecting the transmission of current and signals.

Check the electrical connection of the slip ring: Check the electrical connection of the slip ring regularly to ensure the correct transmission of current and signals.

Check the tightness of the fixed parts: Check the tightness of the fixed parts of the slip ring regularly to ensure that the slip ring will not loosen or fall off during rotation.

Lubricate regularly: For slip rings that need lubrication, add an appropriate amount of lubricant regularly to reduce friction and wear.

Precautions

When using Power Slip Ring, pay attention to the following aspects:

Selection: When selecting, users should consider factors such as application environment, current capacity, voltage range, signal type, speed, life, installation size, weight, maintenance and reliability, and cost. For example, for wind power generation equipment, it is necessary to select a Power Slip Ring that can withstand high speed, high current and high voltage.

Installation: During installation, ensure the coaxiality between the fixed parts and the rotating parts of the Power Slip Ring to reduce vibration and wear. At the same time, pay attention to the safety and reliability of electrical connections to ensure the correct transmission of current and signals.

Working environment: The working environment of Power Slip Ring should be kept clean and dry to avoid damage from dust and moisture. At the same time, avoid using Power Slip Ring under extreme temperature or humidity conditions to avoid affecting its performance and life.

Regular maintenance: Regular maintenance and care of Power Slip Ring is the key to ensuring its long-term stable operation. Maintenance includes cleaning the surface of the slip ring and the brush head, checking the wear of the brush head, checking the electrical connection of the slip ring and the tightness of the fixed parts, etc.

Safe operation: When using Power Slip Ring, relevant safety operating procedures should be followed to ensure the safety of the operator. At the same time, avoid disassembling or repairing Power Slip Ring without authorization to avoid affecting its performance and safety.

Power Slip Ring, as a special electrical connection device, plays an important role in rotating equipment. Understanding its characteristics, functions, application areas, and maintenance and care methods is of great significance to ensuring the normal operation of rotating equipment and improving equipment performance.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions