Standard Products

We have been focusing on providing customers with high quality slip ring products and solutions.

The company's products are not only widely used in civil industry, but also enter the aerospace and military fields.

Definition

Definition

Through Bore Rotary Union, also known as through-hole rotary joint, is a device capable of transferring fluids (including liquids, gases, electricity, or signals) between rotating and static components. It usually consists of an internal channel and an external shell, with the internal channel allowing fluid to flow freely between rotating and static components, while the external shell remains fixed, providing necessary sealing and support.

Characteristics

Excellent sealing performance: The through-hole rotary joint adopts high-quality sealing materials and technology to ensure that the fluid will not leak during transmission, thereby maintaining the stability and safety of the system.

Flexible rotation: Due to the use of a special rotating mechanism, the through-hole rotary joint can achieve 360 degree rotation without affecting fluid transmission, meeting the needs of various complex working conditions.

High transmission efficiency: The internal channel design of the through-hole rotary joint is reasonable, and the fluid experiences less resistance during transmission, resulting in high transmission efficiency.

Strong adaptability: Through hole rotary joints can adapt to different fluid media, pressures, and temperature ranges, and are widely used in various industrial fields.

Function

Fluid transmission: The main function of through-hole rotary joints is to transmit fluids, including liquid or gas media such as water, oil, gas, as well as electricity or signals.

Rotating connection: By using a rotating joint, a reliable connection can be established between rotating and static components to achieve continuous fluid transmission.

Sealed isolation: High quality sealing materials and technology are used inside the rotary joint to prevent fluid leakage, maintain system stability and safety.

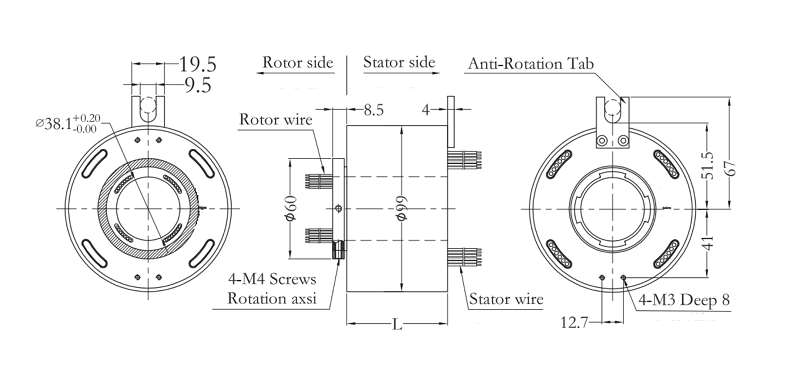

Product Drawings

Application Fields

Agricultural equipment: Through hole rotary joints are widely used in agricultural equipment, such as harvesters, tractors, grain conveyors, etc., for transmitting media such as hydraulic oil and cooling water to ensure the normal operation of the equipment.

Automobile manufacturing: In the process of automobile manufacturing, through-hole rotary joints are used to transmit media such as coolant and lubricating oil, as well as electricity and signals, to ensure the precise operation of automobile manufacturing equipment.

Food processing: Through hole rotary joints are often used in food processing equipment to transfer cooling water, steam, and other media to maintain the stability and safety of food processing equipment.

Paper industry: In the papermaking process, through-hole rotary joints are used to transport pulp, papermaking liquid and other media, ensuring the normal operation of papermaking equipment and the quality of paper.

Plastic industry: Through hole rotary joints are commonly used in plastic processing equipment to transport media such as plastic melt and cooling water, in order to achieve continuous production of plastic products.

Printing machinery: Through hole rotary joints are commonly used in printing machinery to transport media such as ink and cooling water, ensuring the normal operation of printing equipment and printing quality.

In other fields, through-hole rotary joints are widely used in textile machinery, rubber machinery, mining machinery, metallurgical machinery, and other fields for transmitting various fluid media and electrical signals.

Maintenance and upkeep

Regular inspection: Regularly inspect the through-hole rotary joint, including sealing performance, rotational flexibility, and whether the internal channel is blocked, to ensure the normal operation of the joint.

Cleaning and maintenance: Regularly clean the surface and internal channels of the joint, remove impurities such as oil and dust, to maintain the cleanliness and normal operation of the joint.

Replace seals: When seals are found to be aging, worn, or damaged, they should be replaced with new seals in a timely manner to ensure the sealing performance and safety of the joint.

Lubrication and maintenance: For rotating joints that require lubrication, an appropriate amount of lubricant should be added regularly to reduce friction and wear, and improve the service life of the joint.

Avoid overloading: During use, it is advisable to avoid overloading the through-hole rotary joint to prevent damage to the joint or affect its service life.

Precautions

Correct selection: When choosing a through-hole rotary joint, the appropriate model and specification should be selected based on the actual working conditions and medium characteristics to ensure the normal operation and service life of the joint.

Installation specifications: When installing through-hole rotary joints, relevant installation specifications and standards should be followed to ensure the correct installation and sealing performance of the joints.

Usage environment: The through-hole rotary joint should be installed in a dry, ventilated, and non corrosive gas environment to extend the service life of the joint.

Regular maintenance: Regular maintenance and upkeep of through-hole rotary joints can promptly detect and solve problems, ensuring the normal operation and service life of the joints.

Pay attention to safety: When maintaining and servicing the through-hole rotary joint, safety precautions should be taken, such as power-off, shutdown, etc., to ensure personal safety and equipment safety.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions